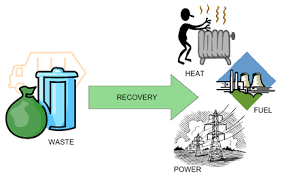

Waste to Energy – Solution for Tomorrow’s Energy

Municipal solid waste (MSW), often called garbage, is used to produce energy at waste-to-energy plants we specializes in design, installation, commissioning, and operation & maintenance of Biogas plants using the most diverse organic waste / feed stocks for generation of electricity, fuel, and bio-fertilizer. The company offers solutions, which are both economically and environmentally sustainable. The individual plant’s capacity range from 30 kVA to 125 kVA and 100 to 1000 M3 per day. The customers include:

Feed Stock

NEERU’s Bio digesters can handle & treat any organic solid waste for biogas generation. The most suitable feedstocks are:

Benefits

Method

Conversion of organic waste into biogas by Anaerobic Fermentation and the gas can effectively be utilized for generation of electricity and cooking fuel. The anaerobic ally treated manure is good compost and promotes bio manure.

Energy Generation

| Sl. No. | Biogas Plant capacity (m3/day) | Replacement of LPG Kg/day | Power Generation Unit Capacity KWh | Electricity Generation kWh/day# |

|---|---|---|---|---|

| 1 | 100 | 40 | 12 | 100-120 |

| 2 | 200 | 80 | 24 | 200-240 |

| 3 | 500 | 200 | 40 | 400-480 |