Renewable Diesel Generation from Animal Tallow / Palm stearin using batch Technology

Animal fat feed stocks result in biodiesel with a high Catani number, which is an important quality parameter for diesel fuels. The saturated fatty acids are the source of this high Cetane number and values over 60 are common. Petroleum-based diesel fuel is usually between 40 and 44. When animal fat biodiesel is blended with petro-diesel, this high Cetane number can help the engine start more quickly and run more quietly.

Why Bio-Diesel?

Although the largest consumption is now produced by fossil fuels, the increasing price, non renewability and the environmental disadvantages of them have caused to seek the suitable alternative fuels. According to the some advantages, such as renewability, lower greenhouse gas emission, more lubricating than fossil fuels and a high flash point biodiesel is one of the most attractive alternative fuels. Moreover, biodiesel does not emit SO2 and or extra amounts of CO2 during the combustion.

BENEFITS OF PROJECT

What is Biodiesel?

Biodiesel is a clean burning renewable fuel made using natural vegetable oils and fats. Biodiesel is made through a chemical process which converts oils and fats of natural origin into fatty acid methyl esters (FAME) and is intended to be used as a replacement for petroleum diesel fuel, or can be blended with petroleum diesel fuel in any proportion.

Raw Materials

Bio-diesel is derived from vegetable oils, spent cooking greases or oils, animal fats, etc. Because plants produce oils from sunlight and air, and can do so year after year on cropland, these oils are renewable. Animal fats are produced when the animal consumes plant oils and other fats, and they too are renewable. Used cooking oils are mostly made from vegetable oils, but may also contain animal fats. Used cooking oils too are renewable and forms as an excellent feedstock for bio-diesel.

Process Technology:

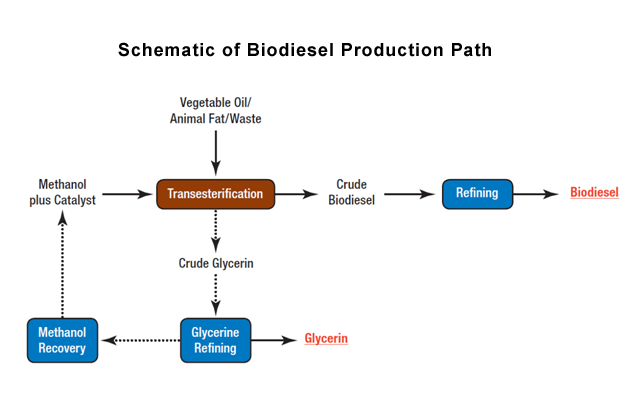

Non Edible oils + Methanol + Sodium Meth oxide Biodiesel + Crude Glycerin

The manufacturing process essentially involves conversion of oils and fats into chemicals referred to as fatty acid methyl esters (or FAME), or simply known as bio-diesel. As a thumb rule when about, 100 kg’s of oils or fats are reacted with 10 kg’s of alcohol like methanol in the presence of a catalyst like Sodium Methoxide (CH3ONa) yields approximately 100 Kg’s of Bio-diesel and 10 kg’s of by-product Glycerin. Steps involved in this Batch technology process are